Climate Friday | 3D Printing – What’s new and how to overcome barriers for this sustainable solution

21 July 2021

31st July 2020

3D printing of elements has the potential to revolutionise the building industry with the promise of less waste, greater flexibility in design and more economical designs. With so much to gain from advancements in this technology Project Engineer Corinna Datsiou, and Graduate Engineer Dennis Behnoud, explore why the building industry is lagging behind so many of our industrial neighbours and how to overcome the barriers to its uptake.

3D printing – what are the key advantages?

The time consuming, energy intensive and costly subtractive and cast manufacturing processes of the past have now been replaced. Now highly complex geometries can be formed by adding material in a layered fashion. High levels of customization in conjunction with topology optimization tools can also now facilitate material efficient designs, taking into account case dependent constraints (load, deflection, stiffness and boundary conditions) all while maximizing their performance.

Additionally, additive manufacturing opens new opportunities for functional grading in the form of single or multi material parts. The composition and microstructure of these novel materials can be gradually modified through the part’s geometry to optimize their material properties (porosity grain size, fiber orientation etc) for a particular function.

Such tools and processes have been already successfully applied in real world applications in the aerospace and automotive industries where lightweight structures are highly sought after. Distinctive AM developments are also reported in the medical and pharmaceutical industries.

But what is the status quo for additive manufacturing (AM) in the building industry and why does it lag behind other sectors?

Despite the cost of the substrate material, the high cost of AM equipment is still a factor. Size limitations, the requirement for post-processing in many cases of AM, parts and the availability /reliability of conventional manufacturing methods with their corresponding design regulations compromise the application of AM technologies in the construction sector.

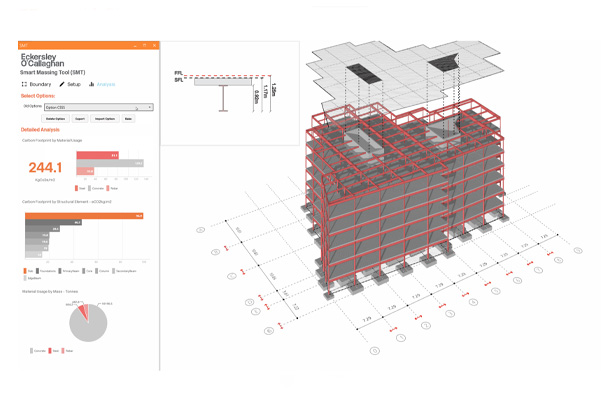

But even with these restrictions headway could still be made. Additive manufacturing techniques could be used to produce small scale components such as 3D-printed structural nodes, connections, stiffeners etc designed though topology optimization tools. However, we should be ready to embrace larger scale AM lightweight structures, that make efficient use of materials when these limitations are overcome, ushering us into a more sustainable future.

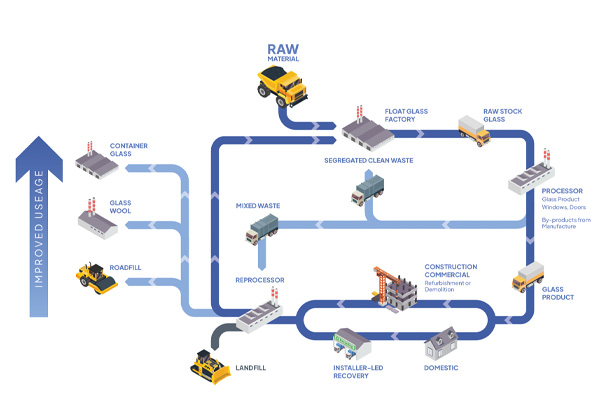

Even though AM is still not established in the construction sector, notable examples can already be found for metals or concrete. Novel wire-based methods that provide automized on-site welding (e.g. Wire Arc Additive Manufacturing), are already on track in the construction industry to improve deposition rates, energy- and material efficiency. This is compared to conventional manufacturing methods or typical AM methods used for smaller metal parts such as selective laser melting. An example of the Wire Arc technology, on which Dennis undertook his master’s thesis, has already been demonstrated in a 3D-printed bridge over flowing water by researchers at TU Darmstadt (Figure 1).

Exciting developments are also found in the concrete industry; these mostly focus on extrusion of cementitious materials through nozzles, operated by robotic arms. This can then be combined with steel reinforcement e.g. the 2-storey office building, manufactured by Apis Cor in Dubai (Figure 2).

AM methods on other commonly used building materials such as glass, are however in their primitive days, even though optimistic results have been reported by Corinna and her fellow researchers at the University of Nottingham. Their finding supported laser powder bed fusion as a promising technology for manufacturing small scale, complex geometries made of glass (Figure 3).

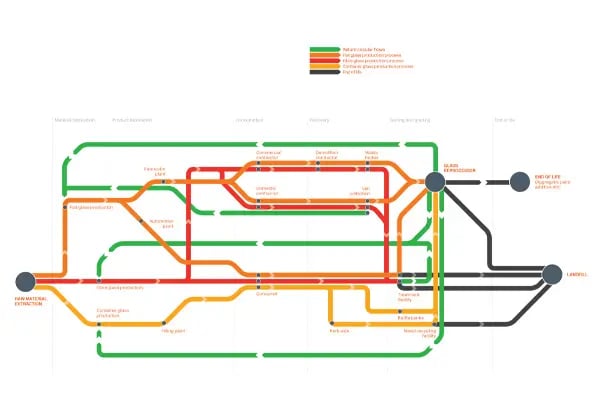

Sustainability should be a key part when using AM technologies. Comparing different materials and the available AM processes for a specific application would be the way forward. We are also looking to start a detailed life cycle assessment would be a valuable tool for evaluating the embodied carbon related to 3D-printing.

How are we contributing?

We can help determining situations where certain processes can be used in potential future applications looking at which can be used on-site effectively or not. Many highly automated processes are controlled by the digital input of programming code, so we can also help with the understanding both the code and digital optimization.

This is an area that through our research we are following very closely with ultimate goal of deploying intelligently fabricated elements on projects soon. We welcome collaborators – Get in touch!