Climate Friday | Circular economy of facades

7 July 2021

A modern facade is made as a kit of parts, with each component having a different lifespan. In our latest Climate Friday instalment, Facades Director Damian Rogan explains why the current regulation of simply stopping materials going to landfill doesn’t go far enough and why we should be thinking more about the circular economy of facades by designing systems that can be dismantled and each component reused or repurposed.

“Today’s facades are a wonder of modern industrial manufacturing. All the building facades we design are unique in one way or another, and they are realised through combining mass-produced components that are often completely custom-designed for our project. They are brought together via sophisticated supply chains and installed with impressive accuracy. Over their lifetimes they will be subjected to intense wind gusts, harmful UV radiation, driving rain, and the occasional impact, and they’ll have been carefully detailed and tested to meet onerous performance criteria for the duration of their service life.

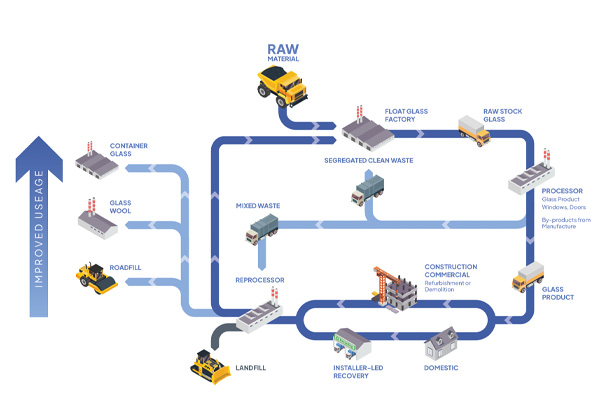

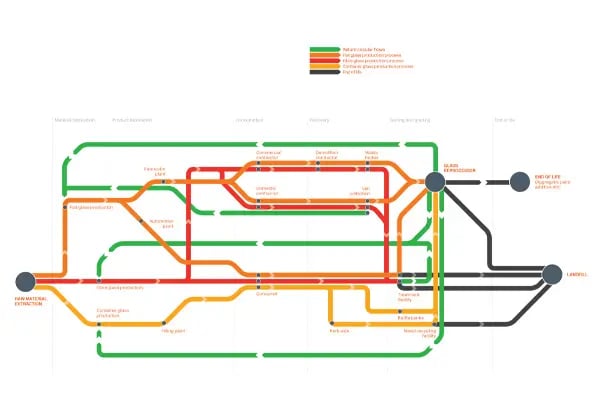

But then what? At some point the individual components of a facade reach the end of their useful service life and need to be replaced, and the problem with facades is that each individual component has different service life: structural components may last 100 years or more, but the corrosion protection for exterior metals will likely degrade before then; while the sealants and coatings that make up an insulated glazing unit will fail long before the glass itself does.

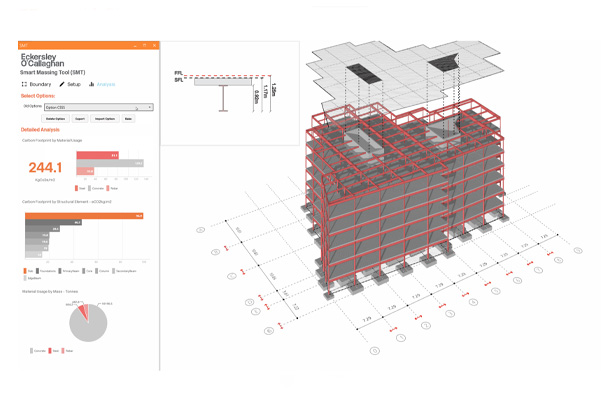

Knowing this, we can design and detail facades to ensure they can be upgraded and kept at a serviceable performance beyond the lifespan of the shortest-lived component. But today we are thinking much more carefully about circularity in facades, and we need to take this thinking further.

It’s not just ok for us to be able to remove a component at the end of its life, we also need to make sure that component is optimised for how it will be recycled or repurposed. We might already detail a facade so we’re able to remove an insulated sandwich panel at its end of life, but do we detail the sandwich panel so that the individual materials can be separated? And are we able to put those individual materials to the highest value use?

To really embrace circular design in facades we’ll need to change our approach to detailing, and this will have an aesthetic and tectonic impact. It’s well known that bricks walls built with cement mortar can’t be reclaimed at their end of life. Do we need to return to using lime mortar as standard? Adhesive bonding makes recycling more difficult, so should we favour using capped curtain wall glazing rather than flush silicone-bonded glazing?

These are questions architects and contractors will need to respond to if we are to embrace a construction culture that prioritises the need to effectively separate materials and supports a circular economy.”