Climate Friday | Cutting carbon – Why isn’t CLT standard for student housing?

16 July 2021

19th June 2020

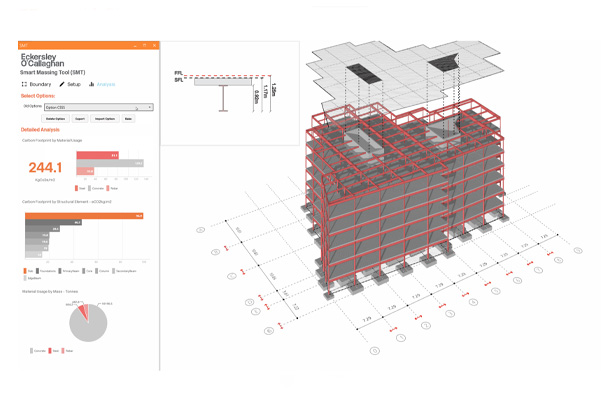

Using cross laminated timber (CLT) can cut the embodied carbon of low rise student accommodation by up to two-thirds when compared to concrete our studies have shown. So when the availability of CLT has increased and the cost decreased, Senior Engineer Ben Lumb asks why isn’t CLT the default material choice for this type of building?

Designing for CLT is rapidly becoming a day to day occurrence for us. We all talk about how timber is a sustainable option, but as at EOC we like having the data to back this up, we decided to do our own calculations on it. This led us to do a study* for one of our current projects for some low rise student accommodation to prove just how much carbon could be saved.

The results were dramatic. For a four-storey CLT block it contained just a third of the embodied carbon compared to the all too often default option – a concrete framed building with stud partition walls to form the living spaces within. The concrete option came in at a whopping 272 kgC02e/m2 compared to just 87kgC02e/m2 for the CLT frame. Other options such as a light steel frame (134 kgC02e/m2), and a steel and pre-cast plank frame (182 kgC02e/m2) were considered, but the CLT still triumphed.

The reason behind this impressive feat is because like all good building materials, the CLT lends itself so beautifully to the application.

Where in other schemes additional partition walls are needed (which adds to the carbon), student accommodation is naturally segmented, lending itself perfectly to a CLT frame using the shear walls as partitions.

For low rise accommodation, the fire requirement is 60 minutes, a rating which is easily met by the CLT with a simple plasterboard covering on the walls and minimal thickness screed topping on the floor slabs. This screed also serves to dampen any vibrational issues which might arise.

The lightness of the timber frame compared to the other solutions also means a less carbon intensive foundation can be used. Where the concrete frame needed a piled foundation, the lightness of the CLT meant only ground beams were needed – a saving not only in embodied carbon, but cost as well.

By knowing how to design in timber, the use of this material can lead to beautiful, cost effective, efficient and most importantly low embodied carbon building. Why design in anything else?

* the study was completed using our own carbon calculator which has been verified, tested and benchmarked against extensive internal and external data.