Climate Friday | Putting embodied carbon on the concept menu

19 July 2021

10th July 2020

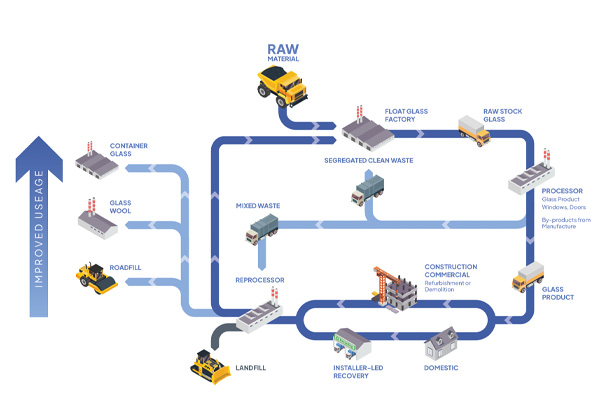

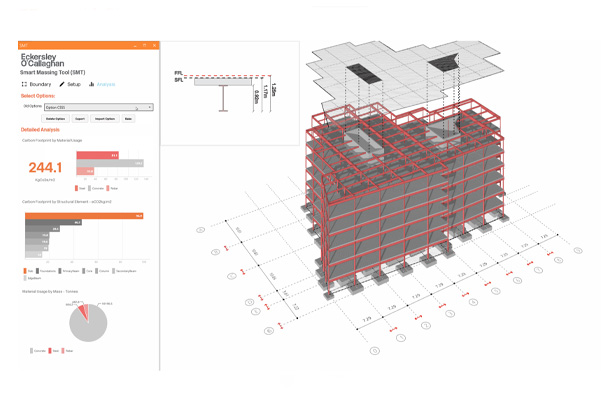

Putting embodied carbon front and centre of the discussion on materiality at concept stage is key for the design team as a whole to make informed choices about the materials we choose to take forward.

In our latest Climate Friday piece, we’re sharing a snippet from a project we are working on at the moment to show how easy it can be to incorporate this information in a meaningful and easily comparative way.

For the project, we have produced a concept menu, a high impact illustration to give the client, quantity surveyor and wider design team the opportunity to comment on the ‘set menu’ of steel-framed options available.

We explored structural depths and floor panel materiality which outputs both steel tonnages and embodied carbon. A total of nine options were made available – there are of course more permutations available, but we have tried not to overwhelm the team at this stage. Once we home in on a particular option the evolution of an idea will continue throughout the design stages.

But getting the right solution, the decision for which take all of the considerations into account, is key. Once the design is fixed at the end of concept stage, the opportunity to consider materiality, and it’s embodied carbon value, is lost with a project rarely looking back at these decisions.

In this example, you can clearly see there is a strong link between steel tonnage and embodied carbon as you would expect. Solutions that push structural depths to a minimum have big embodied carbon as well as cost impacts in steel construction. Lowering building embodied carbon will require a more efficient structural depths to be used. There is a 40% reduction in embodied carbon between shallowest and most efficient structural depths.

That is why visual communication of design options to clients and designers alike is a key aspect of our role.

Note

As the debate on carbon sequestration in timber structures continues to rumble on, and to fuel the debate further, our carbon values assume that a membrane is installed between the timber and the screed layer which makes for ease of re-purposing of the timber panels for future generations. We must begin to take advantage of the carbon benefits of timber construction and the careful decommissioning of structures must be employed at the end of a building’s lifespan. Future generations will rely upon this.

We are exploring full timber frame options in parallel to this, but it is interesting to see the number of permutations that exist within the domain of steel frame primary structure.