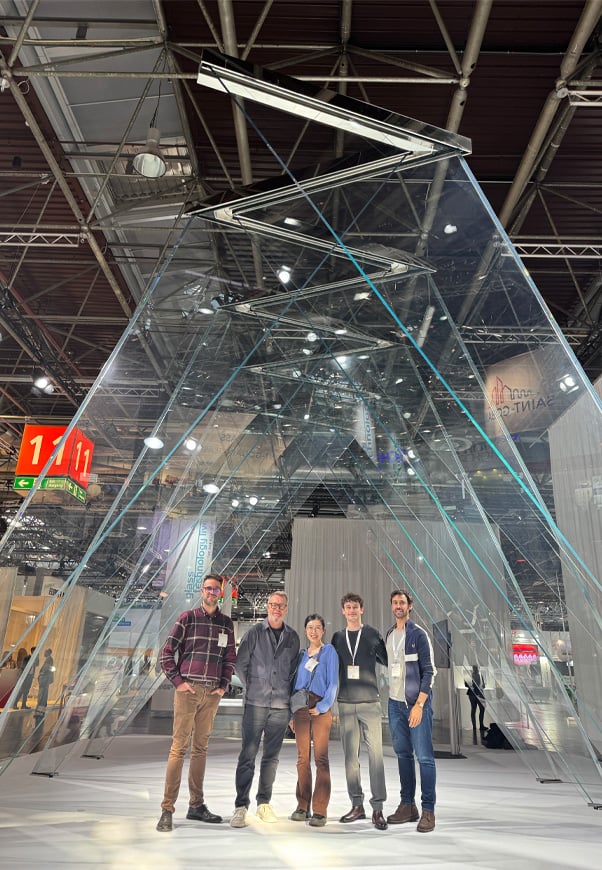

Wonova: the future of facades?

11 November 2022

We’re often asking ourselves what the facade of the future will look like. Will buildings be clad in new materials we haven’t invented yet, like super-insulating, energy-generating switchable glass? Or will we return to more traditional forms of construction using natural materials that can be reused or repurposed at the end of their lives?

Facade Director Damian Rogan and Project Engineer Anaëlle Quillet tell us more following collaborating on a research project on this topic with Etcetera.

Facade engineering is a field where new materials and fabrication technologies are constantly being introduced, and also where performance parameters are evolving to meet sustainability demands and client expectations. It can be difficult to keep up with the present, let alone predict the future.

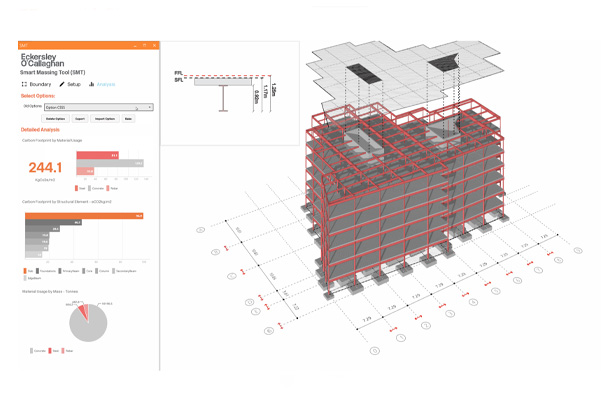

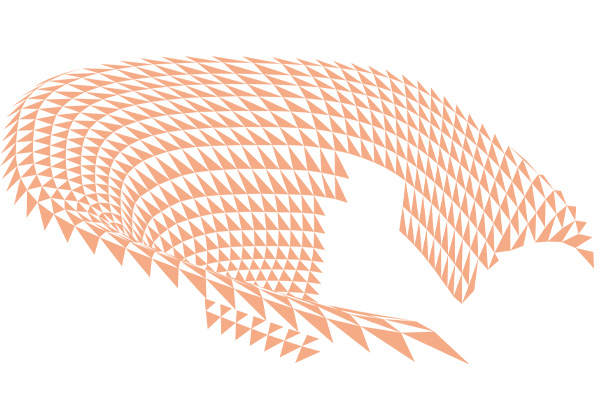

But one emerging technology we do believe has the potential to revolutionise construction is robotic 3D printing. While we tend to think of 3D printing in the context of material optimisation and free-form geometries, one aspect that interests us is the possibility of building lattice structures with varying structural density and porosity to create different functions.

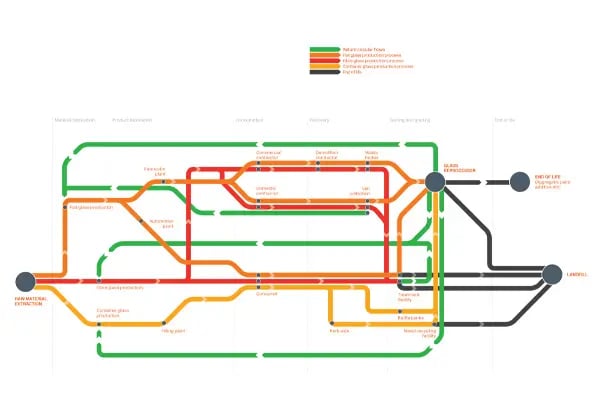

In late 2021 we were approached by long time collaborators Etcetera, who had just succeeded in gaining grant funding to study potential applications of 3D printed facades. Following nine months of research, the result of our collaboration is Wonova, a building enclosure platform that replaces a typical multi-layered facade build-up with a unified single-material construction. Thermal, structural and weather-proofing performance are all provided by the single polymeric material, with air cavities calibrated to achieve different U-values as needed, and lattice density increased where required for structural purposes.

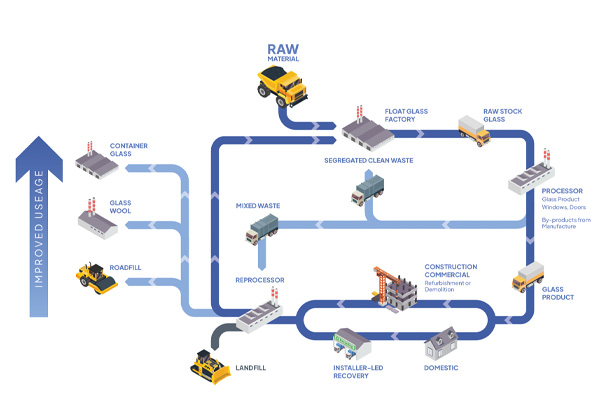

Using polymers made from upcycled plastic waste, we can achieve a substantial reduction in lifetime embodied carbon compared to traditional rain screen cladding. Moreover, the facade can be recycled and repurposed for new buildings through ‘refabrication’ at the end of its life. Using robots to construct the facade on-site reduces transport and logistics challenges and avoids material waste in construction.

Whether we can expect 3D printing to make its way into mainstream facade construction in the near future remains to be seen, but our work has convinced us that it can offer enormous environmental benefits to facade design, and that potential can’t be ignored.

Eckersley O’Callaghan credits: Anaëlle Quillet, Damian Rogan